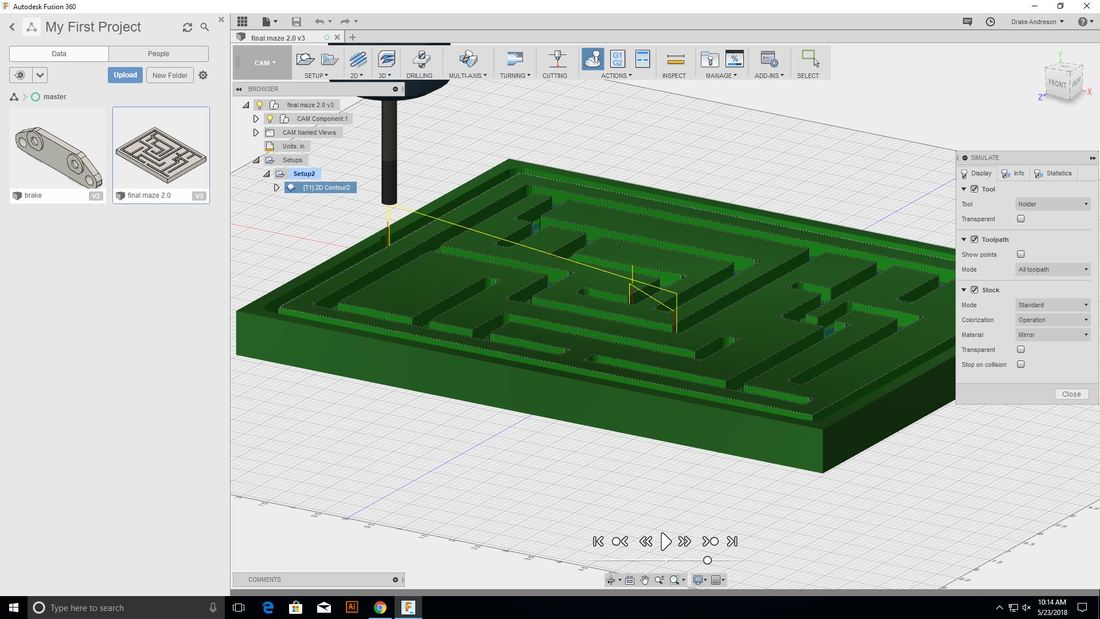

It's titled a "tutorial" but he goes rather fast through some steps so it seems to me more like an introduction to give you a flavor of what it can do, not really a step-by-step tutorial. Here's a Fusion 360 CAD+CAM introduction video.

The post-processor is available from a link in the Software section of that page, along with instructions for using it in Fusion 360. Note: The latest version of this post-processor file is now maintained on my web site at, where I have also published details of a new modular CNC controller that I made to run my Shark and other machines. tap showing the overall part size and the total tool travel range in each axis, which I find a useful sanity check to help prevent tool crashes. tap file that show the toolpaths and the tool types in use, to make sure it's what you expected. Just pay attention to the comments in the. but it doesn't require them to be exactly the same tool because they might differ by non-critical parameters such as cutting length, and even if it flags them as different you have the option to continue. I included code to check for this and to display a warning if the tools are of different basic types, diameters, tapers etc. tap file it generates can be loaded into the regular control panel and run.įusion 360 will run the post-processing with whatever toolpath(s) you have selected, and when using multiple toolpaths they should all use the same tool. Just copy the file there, and then it should show up in the drop-down Post Configuration list next time you open the dialog.

At the top it will show the Configuration Folder where post-processors are stored. cps and then in the Fusion 360 CAM workspace, select Post Process. To install, rename the file extension to. Fair warning, I've only used it on a few simple projects so far and I've only been using millimeters so I haven't tried it using inches. I offer this with no guaranty of course, so use at your own risk but so far it has worked well for me. I didn't base it on one of the AutoDesk post files because mostly they're overcomplicated for what the shark can do (we don't need code for coolant, tool changes, radius compensation etc.). The only stumbling block was that there was no post-processor for the CNC Shark, so I wrote one. AutoDesk licenses it free (as in actually FREE) for hobbyists and business making under $100K/year so it's very attractive for a hobbyist like me. I especially like the built-in 3D CAM capability so I can go straight from my 3D model to generating toolpaths in the same application. The learning curve is a lot steeper than something like VCarve but it can do much more and there are lots of tutorials out there (check out NYC CNC on YouTube). I recently started using AutoDesk Fusion 360 for 3D modeling and so far I'm really liking it.

0 kommentar(er)

0 kommentar(er)